Home » Blog » Automation controls » Frequency Inverter Direct Digital Control

Frequency Inverter Direct Digital Control

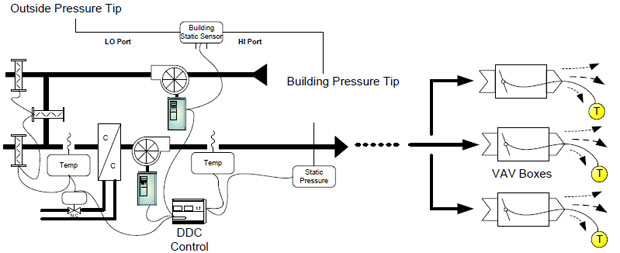

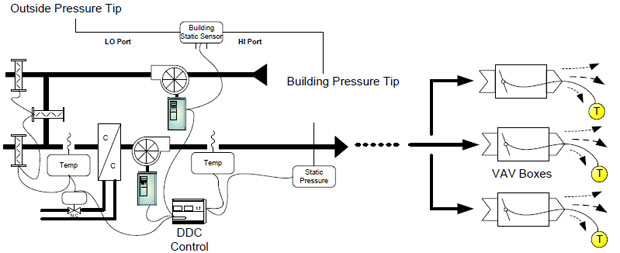

Modulating Supply & Return Fans are used as a means of providing proper variable air volume (VAV) control as well as building pressurization. Many such VAV systems are still largely pneumatic with static to the downstream boxes being maintained by inlet guide vanes. To provide increased energy savings and energy comfort, these systems can be easily converted to frequency inverter fan control of the supply and return fans and Direct Digital Control (DDC) to coordinate any increased energy saving strategies. Figure 1 shows such a system.

To increase energy savings, the DDC controller can be programmed to reduce the flow from the return & supply fans for short periods of time. Coordinated with the building pressurization system, any temporary loss of space temperature may be avoided.

In Figure 1, the supply fan is controlled by the duct static pressure sensor, via the DDC, while the outside air and mixed air dampers are optimized to provide economizer control.. The return fan is modulated to stabilize building pressure at a slight positive. For simple supply and exhaust systems the building pressure and static pressure sensors may be connected directly to the frequency inverter with an internal PID controller.

Typical Energy Savings are realized from converting pneumatic (or electromechanical) control to DDC control with frequency inverter in the following ways:

To increase energy savings, the DDC controller can be programmed to reduce the flow from the return & supply fans for short periods of time. Coordinated with the building pressurization system, any temporary loss of space temperature may be avoided.

In Figure 1, the supply fan is controlled by the duct static pressure sensor, via the DDC, while the outside air and mixed air dampers are optimized to provide economizer control.. The return fan is modulated to stabilize building pressure at a slight positive. For simple supply and exhaust systems the building pressure and static pressure sensors may be connected directly to the frequency inverter with an internal PID controller.

Typical Energy Savings are realized from converting pneumatic (or electromechanical) control to DDC control with frequency inverter in the following ways:

- Locking inlet guide valves mechanically open to allow the frequency inverter to fully modulate the fans.

- Free cooling by accurately modulating the economizer dampers and sequencing the mechanical equipment.

- Controlling static and resetting the static pressure during short periods of time.

- Accurate building pressurization.

- Implementing other energy saving measures which include supply air reset, and night purge routines.

- Placement of the indoor static pressure sensor is important as it should provide a stable signal. Entrances, dock, and other areas where large , sudden static pressure changes may occur should be avoided.

- The outside reference static tip should be shielded from wind and rain.

- When the exhaust fan is frequency inverter controlled, consider a 2-position air damper to prevent the outside air from entering the building (infiltration) when the exhaust fan is off or a very low speeds.

- For simple VAV systems, consider using frequency inverters with built in PID controls such as the Gozuk frequency inverters.. This minimizes hardware and installation costs. Static sensors provide a 0-10vdc control signal directly to the frequency inverter.

- Duct mounted static pressure sensor should be mounted 2/3 of the distance of the distribution system.

You may also like:

Equivalent active power losses during electrical motor's testing in no-load conditions contain next losses:

1. active power losses in the copper of stator's winding which are in direct relation with square of ...

Had run into a very serious field failure issue a decade ago due to IXYS FETs used in a phase-shifted ZVS bridge topology. Eventually, the problem was tracked to failure of the FETs' body diode when the unit ...

Paralleling IGBT modules where the IGBT but not the diode has a PTC is commonly done at higher powers. I personally have never done more than 3 x 600A modules in parallel but if you look at things like high ...

Humidity plays important part in flashover. We faced a problem of flashovers in Air insulated 11kV Switchgear busbar compartments in rainy seasons. Any sharp edge will ionize the surrounding air, which becomes ...

1. To reduce the manpower & the CTC due to them.

2. Few skilled technicians can run the automated machines smoothly, with much lesser number of errors & faults (as human is not directly controlling ...

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.Featured

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

In Discussion

Best place to inject signal for loop gain measurements?

Quick question: South facing roof

Cable Jointing

Will altitude of 3000m be of any problem for insulated 11kV ABC cable?

Transformer for HF Series Resonant Inverter

Which brand do you install in a control system?

Harmonics source detection method

Practical difference between Sink and Source in PLC

Quick question: South facing roof

Cable Jointing

Will altitude of 3000m be of any problem for insulated 11kV ABC cable?

Transformer for HF Series Resonant Inverter

Which brand do you install in a control system?

Harmonics source detection method

Practical difference between Sink and Source in PLC