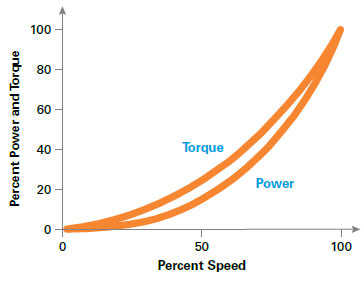

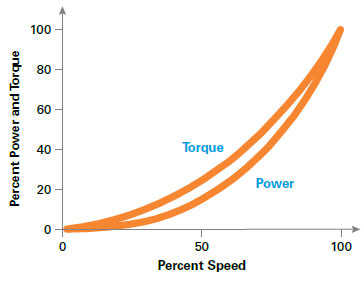

The potential for variable frequency drive (VFD) energy saving from slowing down the load depend on the characteristics of the load being driven. There are three main types of load: variable torque, constant torque and constant power.

Variable torque loads are typical of centrifugal fans and pumps and have the largest energy saving potential controlled by variable frequency drives. They are governed by the Affinity Laws which describe the relationship between the speed and other variables.

Variable torque loads are typical of centrifugal fans and pumps and have the largest energy saving potential controlled by variable frequency drives. They are governed by the Affinity Laws which describe the relationship between the speed and other variables.

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable frequency drives) of fans together account for 50% to 60% of the total electricity used. Centrifugal fans are the most common but some applications also use axial fans and positive-displacement blowers. The following steps help identify optimization opportunities in systems that consume substantial energy running the fan with VFDs.

A typical variable torque application would be a centrifugal pump. A typical constant torque application would be a conveyor, and there are positive displacement pumps that are also constant torque. Have a talk with a mechanical engineer, get them to show you curves and explain.

It will cause a series problems during AC drive operation in various environmental conditions, take an example as: when failure occurs, AC drives protective function is activated, and the AC drive tripped immediately, the electric motor stop slowly, the red LED alarm indication turns on, the display panel shows alarm message code or fault content. Then we can analyze the variable frequency AC drive fault reasons base on the display information, if it is soft failures, we can cut of the AC drive and reset it.

As far as I know all variable frequency drives with vector control can also be run with just V/F control.

A drive in vector control mode has several tuning parameters to increase or decrease motor performance. With factory default parameters a VFD in vector mode will have higher performance than a drive in V/F mode. Sort of like a "sport or racing" computer option in a modern automobile.

For long cables, the combination of cable impedance, high frequency input impedance of motor and VFD switching frequency can lead to reflection of voltage pulses that gives origin to large voltage overshoots on motor terminals. The problem increases as increasing switching frequency because the time between voltage pulses will be smaller, so, a voltage pulse reaching the motor will add to the pulse being reflected.

We recently evaluated a 500 HP 4 pole motor on a pump application. The motor is started with a soft starter. Upon examination of the bearings we discovered fluting inside both the variable frequency drive and opposite drive end bearings.

It's always best to first check with your VFD installation and operation documentation. It is likely that the drives manufacturer makes recommendations for reactor ratings. That said 3 to 5% reactance at the VFD drive's rated input current is always a good solution. If there is no internal bus choke or reactor in the VFD then use 5%. Don't sweat the voltage drop. The drop is in quadrature to the source voltage and so mostly subtracts at a 90 degree angle. Thus, the drop will be less than half the %reactance.

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.Featured

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

In Discussion

VFD used as main power supply question

How to select a breaker??

Vibration in Vertical Pumps

Determine the effect of reduced power factor on the real power consumption

Convert 3 phase motor into 1 phase motor?

Hipot testing of Electric Machines

Advantages/Disadvantages of String inverters vs. Central inverters?

OVP and Noisy Output Voltage problem with Single Stage LED Driver

How to select a breaker??

Vibration in Vertical Pumps

Determine the effect of reduced power factor on the real power consumption

Convert 3 phase motor into 1 phase motor?

Hipot testing of Electric Machines

Advantages/Disadvantages of String inverters vs. Central inverters?

OVP and Noisy Output Voltage problem with Single Stage LED Driver