Variable Frequency Drive (VFD) for Pumps

Like fans, using a variable frequency drive (VFD) to control the flow rate from a pump rather than using simple throttle control can result in large power – and therefore cost savings. This is illustrated in following Figure, where the broken line indicates the power input to a fixed-speed motor and the solid line indicates the power input to a variable frequency drive. The shaded area represents the power saved by using a variable frequency drive for a given flow.

Note: When operating at near full speed there is a crossover point where variable frequency drive control can use more energy than fixed speed control with a throttle. This is due to the losses in the variable frequency drive exceeding the savings from the speed reduction.

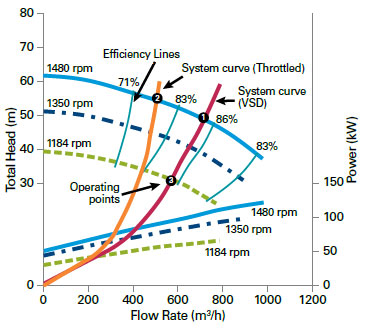

In a similar way to using damper control in fan applications, using throttle control for pumping applications results in a drop in pump efficiency, whereas the efficiency remains higher when the output is regulated by speed control. This is illustrated in Figure.

The original fixed speed operating point (1480rpm) of the pump is at (Point 1) where the system curve intersects the head-flow profile at a flow rate of 700m3/hr, the efficiency is circa. 85.1%. If the output is regulated by a throttle the system curve effectively moves to the left (Point 2) where the pump efficiency has declined to 78%. Conversely if the output is regulated by speed control the operating point moves down the system curve (Point 3) whilst the pump efficiency declines marginally.

On systems with a high static head, in particular pumping applications for example, boiler feed-water pumps or high lift applications, where the pump must overcome the resistance to lifting the water before any flow starts, the benefits of using variable frequency drives will be reduced. This is because higher speeds need to be maintained in order to overcome the additional resistance due to the high static head. Factor this into any calculations (including Affinity Laws) and consult your pump supplier for further information on how to take account of static head.

Typical examples of pump applications that will benefit from variable frequency drives include circulating water in HVAC systems, boiler feed-water pumps, process pumps and other applications where flow demands vary.